Standard

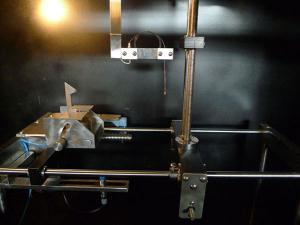

IEC60695-11-5 test flames-needle-flame test method-apparatus

Application

This part of the IEC60695 specifies a needle-flame test to simulate the effect of a samll flame which may result from faulty conditions, in order to assess the fire hazard by a simulation technique.

Test Sample

Lighting, low-voltage electrical appliances, household appliances, machine tool electric appliance, electric motor, electric tools, electronic instruments, electrical instruments, electrical connector, such as electrical and electronic equipment and parts, components, including insulation materials, engineering plastic or other solid combustible materials.

Feature

The needle flame tester consists of a Ф0.9mm needle-shaped burner that tilts with the angle of 45°and provides it with butane gas. The equipment assesses whether the specimen can be ignited by measuring the possible combustion time and length.

Parameters (mm)

| Model | ||

| Working voltage | 220V/50Hz | 220V/50Hz |

| Control operation mode | Electrical control, button operation | PLC control, 7 inch color touch screen operation, with infrared remote control |

| Combustor | Inner boreφ0.5mm ± 0.1mm , OD ≤φ0.9mm , L ≥ 35mm, stainless steel | |

| Gas category | >95% butagas or propane ( can use the bottled lighter gas) | |

| Height of the flame | 12±1mm adjustable (with flame height gauge) | |

| Flame warming requirement | From 100°±5°C to 700°±3°C,time for standard values within 23.5S±1S | |

| Combustion angle | Tilt 45°( testing ) or vertical ( when adjust the height of the flame) | |

| Tray | A layer of silk paper (12~30g/m³) is covered on the 10mm thick pine board, with a distance of 200±5mm below the test sample | |

| Timer/sustained combustion | 0-9999X0.1S | |

| Temperature measuring distance | The distance between the top center of the burner and the test sample:8±1mm | |

| Temperature calibration | Temperature measuring copper head:Φ4±0.01mm, weight:0.58±0.01g | |

| Temperature thermocouple: The American original Omega φ0.5 armour nickel-chromium/nickel aluminum wire K-Thermocouple, temperature resistance 1100° | ||

| Temperature measuring distance:6±0.5mm | ||

| Air volume control | The flame height can be adjusted by adjusting the flow meter | |

| Test procedure | Automatic control, independent exhaust | |

| Lighting | Equip with lighting in the test chamber, with control | |

| Test chamber and dimensions | >0.5 cube, black yogon background, with exhaust fan, size:1100*550*1200mm, weight:130kg | |