The stainessless thin shell shall be filled with SF6 gas. As there might be welding defects, it is necessary to do leak testing before the SF6 fill. The normal solution is the auto helium leak test system.

As the stainessless thin shell can only bear limited pressure, the helium leak test, dryness test and SF6 fill process are completed inside an integrated system.

Test Concept

Evacuate the vacuum chamber.

Check the pressure drop inside the product for gross leak test.

Evacuate the product and charge helium into the product.

Test the helium signal from the vacuum chamber by the leak detector for fine leak testing.

Recover helium from the product.

Charge SF6 into the product.

Vent vacuum chamber.

Technical Specification

Cycle time:1hour/pcs.

Leak rate:1×10-6mbar.l/s

Test pressure:0.5bar

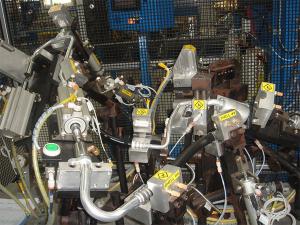

Main Parts of System

Vacuum pump: Leybold

Vacuum sensor: Inficon

Helium leak detector: Inficon

Pressure sensor: GE

Solenoid valve: Burkert

PLC: Omron

HMI: Omron