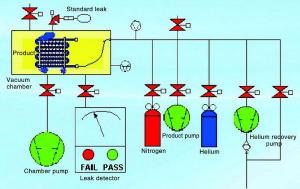

The auto vacuum helium leak test system is used to find any vulnerabilities in automobile parts.

Test Concept

Charge high pressure gas into the product for gross leak test and proof test

Evacuate the vacuum chamber.

Vent gas from the product.

Evacuate the product and charge helium into the product.

Test the helium signal from the vacuum chamber by the leak detector for fine leak judge.

Recover helium from the product.

Vent vacuum chamber.

Parameters

| Components to test | Automobile Parts | |

| Reject point (unit: mbar.l/sec.) | gas venting parts, pipelines of engine | 1.00E-01 |

| Aluminium wheel, fuel cell | 1.00E-04 | |

| Condenser, evaporator, refrigerant pipelines, compressor | 1.00E-05 | |

| storage battery | 1.00E-06 | |

| Fuel nozzle, automobile radiator, automobile heater core | 1.00E-03 | |

| Engine cooler | 1.00E-04 | |

| Fuel tank, fuel pipelines | 1.00E-05 | |

| Gas for Gross Leak Test | Nitrogen or dry air | |

| Pressure for Gross Leak Test | 2-42bar, demanded by working pressure of test piece. | |

| Pressure for Helium Leak Test | 2-42bar, demanded by working pressure of test piece. | |

| Quantity of Test Station | 1, 2 or 3, demanded by cycle time | |

| Products to test in each Chamber | 1 or 2 | |

| Cycle Time | 30sec./pcs, demanded by production rate of test piece | |

| Helium recovery rate | >95% | |

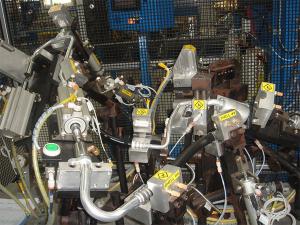

| Test Fixture | Included | |

| Calibration Leak | 2 pieces, one is for system calibration, the other is for daily machine check. | |

| Loading and unloading of Products | Manual or Automatic | |

| Test Cycle | Automatic | |

Main Parts of System

Vacuum pump: Leybold

Vacuum sensor: Inficon

Helium leak detector: Inficon

Pressure sensor: GE

Solenoid valve: Burkert

PLC: Omron

HMI: Omron