Standard

Clause 21.2 of IEC 60335-1 Household and similar electrical appliances - Safety - Part 1: General requirements, IEC 60950 clause 2.10.8.4, and etc.

Application

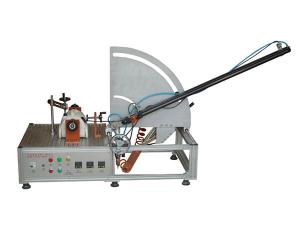

It is used to process scratch testing for the solid insulation boards and accessible parts of house appliances and similar products. This is to ensure that accessible parts of solid insulation shall have sufficient strength to prevent penetration.

Test Sample

Household appliances, printed circuit board.

Feature

The surface of the insulation is scratched by means of a hardened steel pin. The scratches are made by drawing the pin along the surface of the insulation at a speed of approximately 20mm/s±5mm/s. Two parallel scratches are made. They are spaced sufficiently apart so that they are not affected by each other, their length covering approximately 25 % of the length of the insulation. Two similar scratches are made at 90° to the first pair without crossing them.

The scratches shall be at least 5 mm apart and at least 5 mm from the edge of the specimen.

The device adopts a PLC + touch screen control system, stepping motor drive, the scratch distance, scratch times and speeds can be preset, the test pin can rotate 90 ° angle automatically, scratch test in both vertical and horizontal directions can be easily realized.

Parameters

| Input Power | 220V/50HZ |

| Control | PLC control, 7-inch color touch-screen operation, stepper motor driver |

| Station | 1 |

| Scratch Pin | Rounded with a radius of 0,25 mm ± 0,02 mm |

| The end of Scratch Pin | Form of a cone with an angle of 40° |

| Scratching Speed | 20±5mm/s, can be preset |

| Scratching Force | 10N±0.5N |

| Scratches Distance | 0-50mm, can be preset |

| Scratching Angle | 80-85°, fixed by fixture |

| Test Sample Tray | Can be rotated 90 °, multiple mounting holes for the installation of different samples |

| Optional | 30N±0.5N Load Device |